Technical parameters:

|

model |

UV-3W |

|

wavelength |

355nm |

|

laser power |

3W |

|

Beam quality M2 |

<0.8mm |

|

Engraving range |

standard configuration100*100mm |

|

Mark line width |

≤0.01mm |

|

Marking line speed |

≤0.01mm |

|

Minimum character |

0.12mm |

|

Marking speed |

≤10000mm/s |

|

repeatability |

±0.001mm |

|

Cooling method |

water-cooling |

|

Power demand |

Single phase 220V/50Hz/60Hz/16A |

|

Whole machine power |

1.5KW |

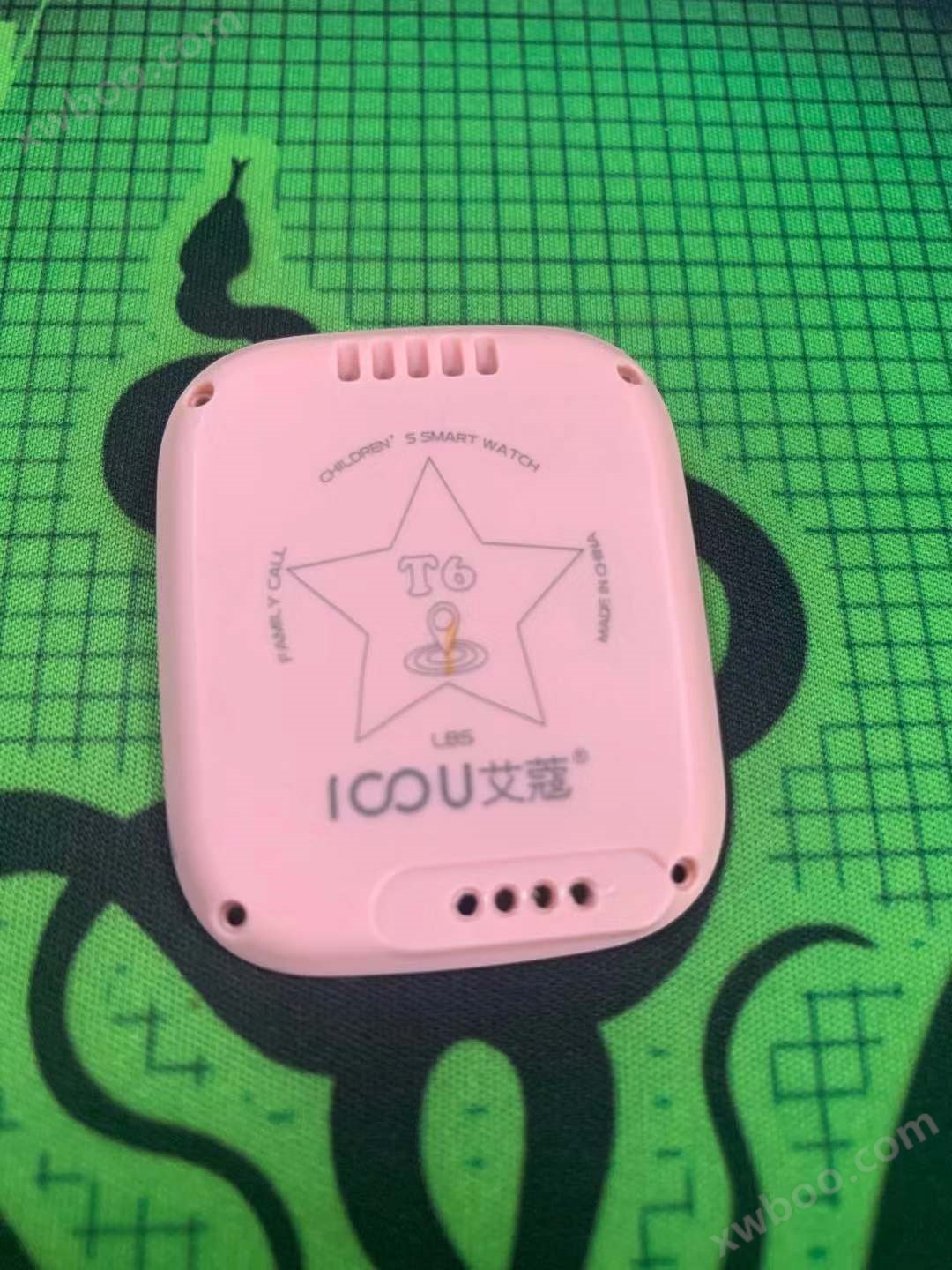

Machine image:

Working principle and characteristics:

Integrating international advanced technology,High energy ultraviolet photons directly break the molecular bonds on the surface of many non-metallic materials, causing molecules to detach from the object. This method does not generate high heat, and the concentrated spot of ultraviolet laser is extremely small, with almost no thermal impact during processing. Therefore, it is called cold processing and is suitable for ultra fine marking and engraving of special materials.

Product advantages:

■UV laser wavelength is shorter and the focused spot is smaller,Can achieve ultra-fine marking;

■ Belongs to cold processing, with a small heat affected zone,Avoid damaging the processed material,High yield rate;

■ Widely applicable materials,Compensate for the lack of infrared laser processing capability;

■ Use high-speed digital galvanometer,Fast marking speed, high efficiency, and high accuracy;

■ No consumables required, low usage and maintenance costs; The overall performance is stable and can operate for a long time.

■

Industry application:

Suitable for surface marking and micro hole processing of objects such as glass and polymer materials.

■ Widely used for marking and micro hole (aperture) on the surface of packaging bottles (boxes) made of high polymer materials such as food, medicine, cosmetics, and wiresd≤10μm).

■ flexibilityPCBBoardLCD、TFTMarking, cutting, etc.

■ Removal of metal or non-metal coatings

Silicon wafer micro hole and blind hole processing.

Sample display:

Product features:

Almost perfect marking quality:355nmThe output wavelength has reduced the thermal impact on the workpiece;Mirror type high-precision marking head, precise marking effect and repeatable processing;High precision and detailed spot ensures perfect marking results;The marking process is non-contact, and the marking effect is permanent:

Wide range of application areas:

More suitable for processing materials with high thermal radiation reactions;Can be coordinated with production lines, automatic loading and unloading, automatic feeding and discharging;Suitable for marking on the vast majority of metal and non-metal materials;

Flexible and convenient operating system:

Humanized operation process and good stability of equipment operation;Specialized control software is compatibleAutoCAD、 CorelDRAW、PhotoshopWaiting for multiple software outputs;Can achieve automatic arrangement and modification of text symbols, graphic images, barcodes, QR codes, serial numbers, etc;supportPLT、PCX、DXF、BMP、JPGMultiple file formats available for direct useTTFCharacter library;CCDAutomatic recognition, tracking, and positioning;

Work environment requirements:

■ The environmental temperature requirement is10-35Between ℃, air conditioning is required to be installed;

■ The temperature requirement is<60%If there is no condensation, a dehumidifier should be installed;

■ Requirements for power grid:220V;50HZ/60HZ;

■ Power grid fluctuation: ±15%The grounding wire of the power grid meets international requirements. voltage amplitude15%Electronic automatic voltage and current stabilization devices should be installed in the above areas;

■ There should be no strong electromagnetic signal interference near the installation equipment. Avoid radio transmission stations (or relay stations) around the installation site;

■ Foundation amplitude: less than50UmVibration acceleration: less than0.05gAvoid having a large number of stamping and other machine tools nearby;

■ The equipment space requirements should ensure smoke-free and dust-free environments, avoiding working environments with severe dust such as metal polishing and grinding;

■ Air pressure:86-106kpa

■ Anti static flooring and enhanced shielding should be installed in certain environments;

■ The water quality of working cooling circulating water has strict requirements, requiring the use of pure water, deionized water, or distilled water. Liquids containing high metal ions or other minerals such as tap water and mineral water cannot be used.

Service process:

If you come to our company in person:

1Contact us by phone to confirm your labeling requirements and sample situation, and schedule a time with you.

2You come to our company, we have dedicated personnel to assist you, conduct on-site sample experiments, and communicate in detail. Through multiple sample experiments, we have selected the most suitable machine model and processing plan!

If you send samples to our company:

1Please contact us by phone to first discuss the labeling requirements and sample situation of the samples you have sent, determine the quantity and variety of samples you have sent, and estimate the expected delivery time.

2After the samples are sent out, please let us know the time of shipment, shipping method, and tracking number so that we can receive the samples as soon as possible and complete the sampling work for you as soon as possible!

3After receiving the sample, we will communicate with you about various parameters and marking requirements, then conduct marking experiments according to the requirements, and record various working parameters to select the most suitable model and solution for you!

4We will send you the sample and inform you of the processing parameters. Based on this, we will recommend suitable machine models and solutions for you!