Hysitron TS 77 Selection is an automated desktop nanomechanical and nanofriction testing system that provides the highest performance, versatility, and ease of use of similar instruments. This new testing system is designed with Bruker's outstanding TriboScope capacitive sensor technology, providing reliable mechanical and tribological characterization at the nanometer to micrometer scale. TS 77 Selected supports mainstream testing modes and is a cost-effective solution for quantitative nanoindentation, dynamic nanoindentation, nanoscratching, nanofriction and wear, and high-resolution mechanical performance imaging.

Nanoindentation - High precision mechanical properties

Describe the local microstructure, interface, micro surface features, and elastic modulus, hardness, creep, stress relaxation, and fracture toughness of the thin film.

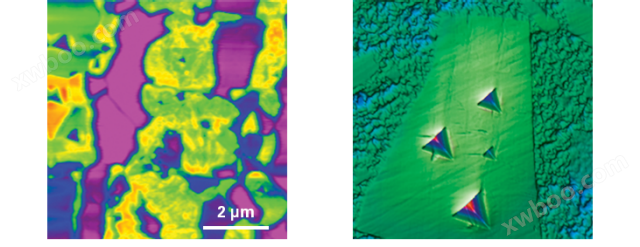

In situ SPM imaging - achieving nanomechanical characterization of * *

Using the same probe to perform in-situ 3D morphology imaging of the sample surface, together with nanomechanical testing, to achieve nanomechanical characterization, data reliability, and nanometer level accuracy positioning.

Mechanical performance imaging - fast imaging and fast data acquisition

Provide high-speed testing function, which is 180 times faster than traditional nanoindentation testing speed. Obtain high-resolution mechanical property distribution maps of non-uniform materials within a few minutes at a testing speed of two nanoindentation tests per second.

Wear testing - quantitative nanoscale wear resistance

Quantitative wear volume and wear rate can be measured as a function of applied contact force, sliding speed, and number of repetitions. Due to the small scale of testing, it is convenient to measure the frictional properties of individual microstructures, interfaces, and films.

Dynamic nanoindentation depth analysis, viscoelastic properties

Dynamic nanoindentation superimposes a small oscillatory force component onto a quasi-static force to continuously measure hardness and modulus as a function of material surface depth. The dynamic nanoindentation option includes gating for dynamic measurements and controllers, providing * * results as a function of testing depth, frequency, and time.

Nano scratches - friction, wear resistance, and film adhesion

Nano scratches utilize electrostatic driven two-dimensional sensors to apply normal force in a controlled manner, while measuring the force required for lateral movement on the sample surface. The nano scratch option does not rely on the lateral movement of the electric sample stage, providing the most sensitive and reliable measurement of nanoscale friction and thin film adhesion in the market.

Simplify system operations and data analysis

Brooke's TS selected control and analysis software package is developed to streamline the measurement process: from loading samples and testing settings to measurement execution and data analysis. The selected control software of TS 77 integrates automatic sample testing and instrument calibration programs for simple, high-throughput, and * * characterization.