Technical Parameter

model |

FL-1 |

FL-2 |

Canned weight |

1 - 500g |

|

Canned precision |

≤100g, 2%; 100– 500g, 1% |

≤ 100g, ≤±1.5%; 100 – 500g, ≤±1% |

Maximum production capacity |

40 bottles per minute |

70 bottles per minute |

Gas source and consumption |

0.6Mpa 50L/min |

0.6Mpa 50L/min |

Power Supply and Power |

AC220V 50Hz 1.2kW |

AC220V 50Hz 2.0kW |

External dimensions |

1200×900×1930mm |

1185×940×1930mm |

What are the advantages of our product?

National standard drafting unit; Industry standard revision and formulation unit; Compliant with GMP requirements

National standard drafting unit; Industry standard revision and formulation unit; Compliant with GMP requirements

The parts in contact with the material are made of SS316L stainless steel, while the other main frames are made of SS304 stainless steel

The parts in contact with the material are made of SS316L stainless steel, while the other main frames are made of SS304 stainless steel

Progressiveness: intelligent joint control of the whole line; Online intelligent detection

Progressiveness: intelligent joint control of the whole line; Online intelligent detection

Economy: Exquisite structure, small footprint; Low energy consumption; Low maintenance cost

Economy: Exquisite structure, small footprint; Low energy consumption; Low maintenance cost

(a) Main motor: ABB/GPG

(b) Pneumatic components: SMC/Air Tac

(c) PLC/microcontroller human-machine interface (touch screen): Faceface/Mitsubishi/Hitech

(d) Electronic components: Schneider/Omron

Widely applicable: Used in industries such as pharmaceuticals, food, healthcare, daily chemicals, and biology

Widely applicable: Used in industries such as pharmaceuticals, food, healthcare, daily chemicals, and biology

production process

sales network

Our products cover all over the world and are popular in developed regions of Europe and America. Repeatedly exported to countries and regions such as the United States, France, Germany, Italy, the United Kingdom, Canada, Australia, Russia, India, Thailand, Singapore, Brazil, Peru, South Africa, Iran, Bahrain, Saudi Arabia, etc.

Our products cover all over the world and are popular in developed regions of Europe and America. Repeatedly exported to countries and regions such as the United States, France, Germany, Italy, the United Kingdom, Canada, Australia, Russia, India, Thailand, Singapore, Brazil, Peru, South Africa, Iran, Bahrain, Saudi Arabia, etc.

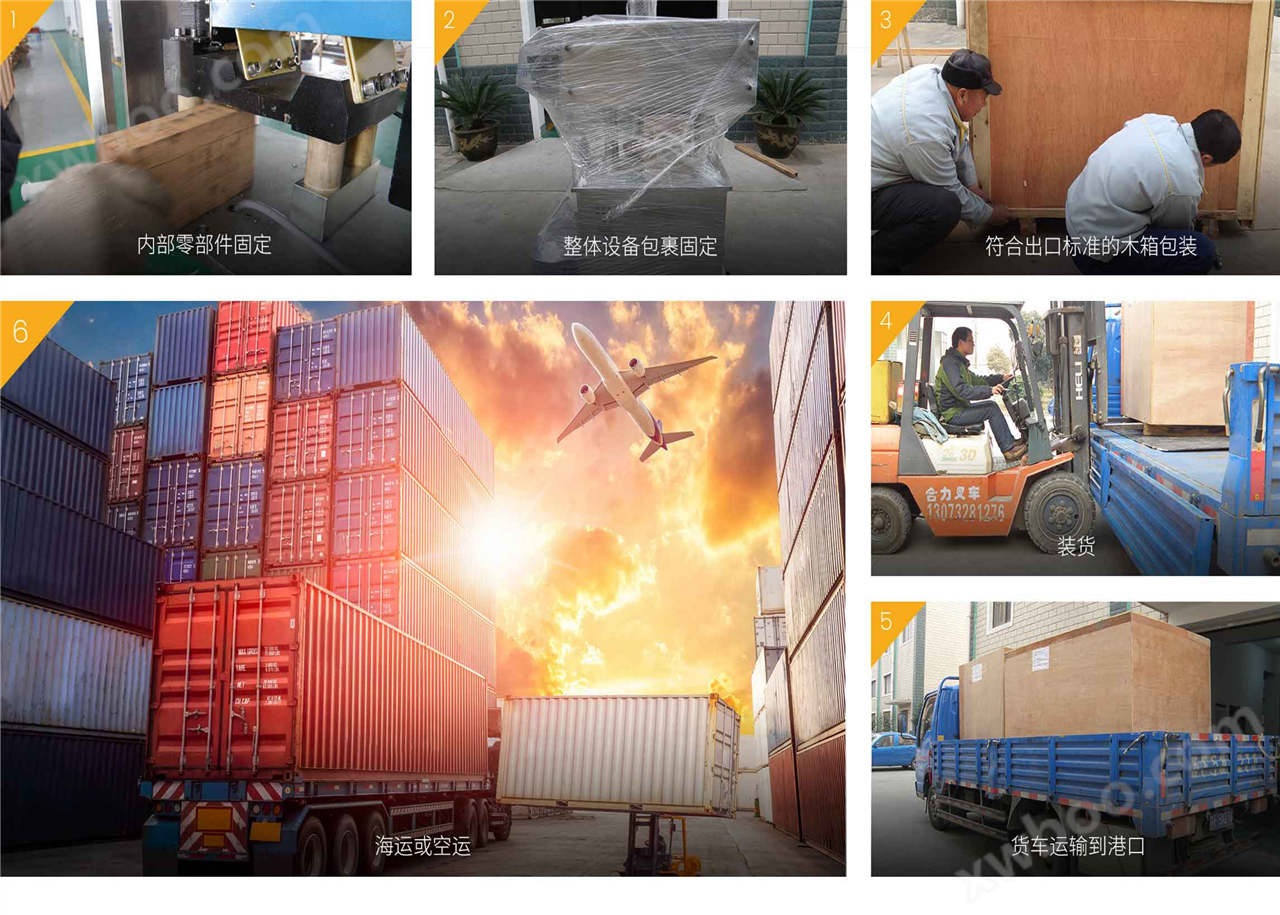

Packaging and transportation