1CK6136D-Y ∠ 30 inclined bed lathe milling composite machine (36 turret+with Y-axis+4-side power head+4-end power head) - high configuration Parameter Table

CKX6136D-Y (turret with Y-axis turning milling compound machine) ∠ 30 inclined bed height configuration table

1

Main technical parameters

Serial Number

Project Name

unit

Project parameter table

※※

moving range

1

Maximum travel (X/Z/Y)

㎜

720/260/180

2

Minimum setting unit (X/Z/Y)

㎜

0.001

3

Speed movement (X/Z/Y)

m/min

22/22/15 (30/30/15 optional)

※※

machine range

4

Swing over bed

㎜

Φ310

5

Maximum processing diameter for disk/shaft components

㎜

Φ280/φ100

6

Maximum processing outer circle length

㎜

200

7

maximum bar diameter

㎜

Φ35

※※

main shaft

8

Spindle end form

A2-4

9

Spindle speed series

level

not have

10

Spindle center height

mm

50

11

Main spindle speed range

r.p.m

45-4000 (design time: theoretical 6000-8000)

12

spindle bore

㎜

Φ46

※※

electrical machinery

13

Main motor power

kw

2.9/3.7 (optional)

14

feed motor

kw

0.85/1.5 (optional)

※※

cutting tool

15

Outer round square knife size

㎜

20×20

16

Internal boring tool size

㎜

φ20

17

Knife changing method

Rotating tower type tool change nearby

18

Tool change time

S

0.2

19

Tool change positioning accuracy

0.003

20

Maximum loading capacity of knife holder

grasp

Knife tower+Y-axis five axis power head

※※

power head

21

Power head motor

kw

0.75

22

Power head speed

3000

23

Maximum clamping of power head

㎜

ER20/φ13

24

Maximum power head attack teeth

M

M8

※※

other

25

Repetitive positioning accuracy (X/Z/Y) at constant temperature

㎜

0.003

26

positioning accuracy

mm

0.005

27

Bed structure

30 degrees

28

The total installed capacity is approximately

kw

9

29

Net weight of machine tool

Kg

2700

30

Dimensions (length x width x height)

㎜

2160×1350×1760

IICK6136D-Y ∠ 30 inclined bed lathe milling composite machine (36 turret+with Y-axis+4-side power head+4-end power head) - high configuration Main Material List

1

spindle

China 3.7KW (Japan Yaskawa 2.9KW) servo motor

2

spindle bearing

Japanese original NSK or German FAG precision grade bearings - (optional according to product processing requirements)

3

Numerical Control System

Beijing KND, Taiwan Baoyuan, New Generation (note: optional Japanese Mitsubishi or Fanuc)

4

Servo system (driver+motor)

Yaskawa, Japan 0.85KW/Maixin 1KW

5

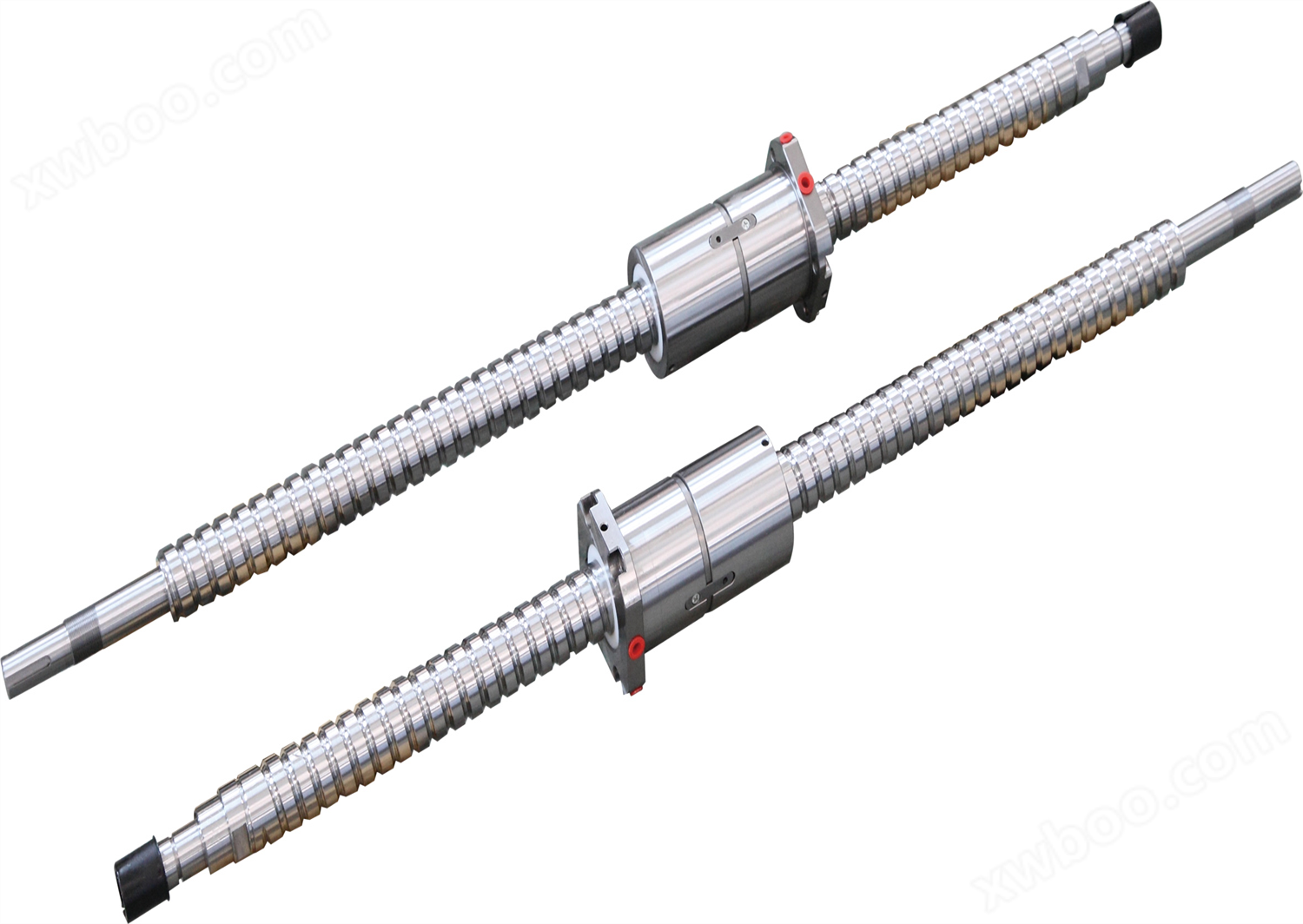

X. Z-axis ball screw

Taiwan Yintai or Shangyin P3 class heavy-duty ball screw (diameter 32)

6

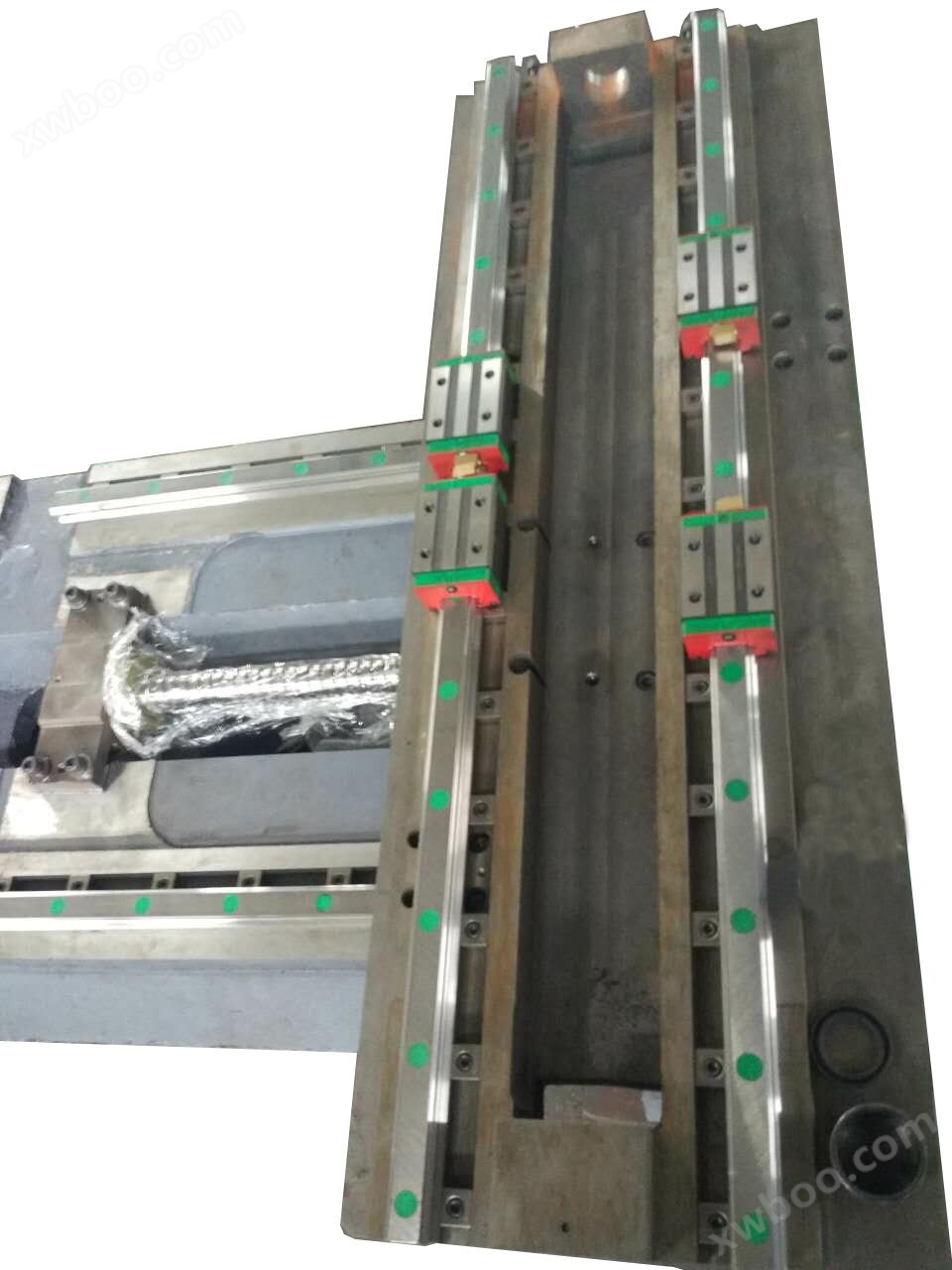

X. Z-axis linear guide

Taiwan Yintai or Shangyin P-type heavy-duty linear guide rail

7

X. Z-axis bearing

Japanese original NSK or German FAG precision grade bearings - (optional according to product processing requirements)

8

Knife holder form

Taiwan Jiasu eight station turret+2 power heads (Jiasu, Liuxin, Xinxin - optional)

9

Hydraulic rotary cylinder

Taiwan rotary oil cylinder

10

Hydraulic station

Taiwan variable oil pump, hydraulic motor, hydraulic solenoid valve+air cooling system

11

Computer lubrication system

river valley

IIICK6136D-Y ∠ 30 inclined bed lathe milling composite machine (36 turret+with Y-axis+4-side power head+4-end power head) - high configuration

Structural characteristics of machine tools

| Construction and features of machine tool structure | |||

| Suitable for heavy loads and continuous cutting, it can maintain long-term high precision and high-quality surface roughness. | |||

|

■High precision, high rigidity, heavy-duty spindle.

|

|||

|

The spindle adoptsOriginal imported NSK or FAG P4 precision grade spindle bearings from Japan or GermanyThrough engineering calculations and analysis, an optimized span configuration has been achieved, coupled with a unique maze style waterproof design and a heat dissipation plate spindle box design, which can achieve better waterproof and dustproof effects. The use of high-tech lubrication technology and high rigidity sleeve structure demonstrates better stability, ensuring greater axial rigidity, radial rigidity, and machining accuracy. Using a dedicated spindle motor and imported frequency converter, it achieves large-scale automatic stepless speed regulation. The entire spindle is produced by a professional spindle manufacturer in Taiwan, Pusen.The main shaft bearings are arranged in a front three and back two arrangementCan better withstand stronger impacts. The spindle design speed can reach 8000rpm/min.

|

|||

| ■Good rigidity, easy operation and chip removal. | |||

|

High strength, bed tilted at 45 °, made of high-quality cast iron resin sand molding, and subjected to secondary annealing treatment to ensure casting stability. The tight ribbed structure has good rigidity and strong seismic resistance. The inclined placement of the large drag plate and tool holder makes the operation and chip removal of the machine tool very convenient, and occupies a small area with good comfort.

|

|||

|

■Imported Taiwan Shangyin or Yintai P-type linear slide rails with high rigidity, high precision, and high speed, C3 precision ball screw, and dedicated Japanese NSK/German FAG screw bearings. The two ends of the screw rod are pre pulled according to the machining center, resulting in higher rigidity.

|

|||

|

The two axis transmission is directly connected by a servo motor and a precision ball screw through an elastic coupling, with good force conditions and high positioning accuracy. Equipped with a computerized automatic lubrication system for forced lubrication of linear guides and ball screws. The X-axis and Z-axis adopt high rigidity linear sliding rails, and the optimized span between tracks is calculated, with low resistance, high rigidity, and high precision. The displacement speed can reach 18-30m/min, improving work efficiency and shortening processing time. |

|||

|

■Hydraulic stationUsing Taiwanese quantitative pumps, hydraulic motors, solenoid valves, and equipped with air cooling devices, the noise level is low and the oil temperature is low.

|

|||

|

■ AdoptingTaiwan Six Xin Eight Station Hydraulic Rotary Knife TowerHigh positioning accuracy, low failure rate, fast tool change, and nearest tool change.

|

|||

|

■ Adopting beautifulFully enclosed protective coverGood waterproof performance. The activity door opens easily and effortlessly.

|

|||

|

The control system and spindle motor adopt servo spindle, and are equipped with two axis radial or axial servo power heads. It can achieve 360 degree arbitrary indexing and positioning of the spindle, as well as drilling, tapping, and milling functions. (Note: Different models have different requirements, and different power options can be selected)Head)

|

|||

|

The machine tool lighting adopts explosion-proof, long-life, high brightness LED energy-saving lamps. The cooling pump adopts a large displacement cooling pump imported from Taiwan.

|

|||

|

The base can be made of integral castings, which have high strength and good seismic resistance, and are more suitable for environments with large temperature differences in the north(Different types of castings are available.)Select).

|

The base can be made of integral castings, which have high strength and good seismic resistance, and are more suitable for environments with large temperature differences in the north

(Note:Different casting modelsItem can beselect).

The base can be made of integral castings, which have high strength and good seismic resistance, and are more suitable for environments with large temperature differences in the north

(The following picture shows the casting part)

Decomposition diagram) - for reference only, assembly of the entire machine is based on actual engineering drawings

Operating System: Mainly usedNew generation systemsMainly based on Baoyuan system (high-end models adopt:Mitsubishi Systems, Fanuc, Siemens)

■ (Optional)CNC lathe oil bath feeding machine