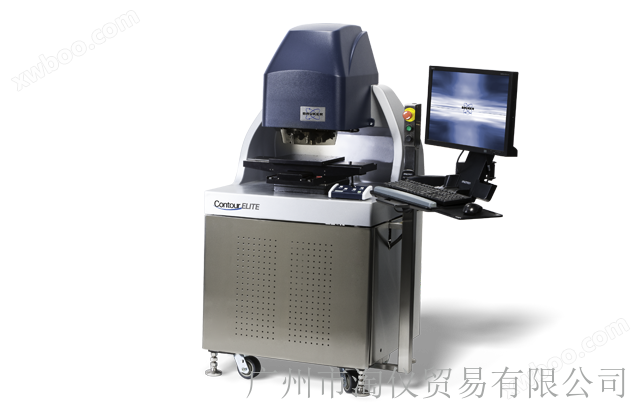

The fully automated Contour Elite X 3D optical profiler combines * * *'s measurement capabilities with the industry's largest field of view and high vertical resolution for high fidelity color or monochrome imaging. No other metrology system provides non-contact accuracy, throughput, operator convenience, and imaging capabilities to address such a wide range of production metrology applications. Designed to meet the stringent requirements of research and development, quality assurance, and process quality control,Contour Elite XProvided the ultimate measuring tool capability 3D optical profiling solution.

Combining color imaging with metrology

Additional high fidelity color imaging, side lighting, and * * algorithms enableContour Elite XUsers have access to additional perspectives, systems that cannot be provided, the ability to provide metrology alone, and the ability to report identifiable surface feature details. This enables users to segment data based on color or grayscale information to quickly select areas of interest and collect key metric data from these specific areas. Combining excellent metrology with the ability to observe, identify, and display measurement results is crucial not only for understanding data, but also for communicating results.

*Excellent horizontal and vertical resolution

Contour Elite XThe system has a great combination of horizontal and vertical resolution that exceeds the industry's maximum field of view, with a vertical range from sub nanometer to over 10 millimeters. It includes the acupuncture and moxibustion XR measurement technology of the R&D 100 Award, which provides a way to break the diffraction limit in your optical measurement. In addition, the system can also use a million pixel camera to improve the X-Y spatial resolution The large field of view and objective magnification ranging from 1x to 115x enable the description of an extremely wide range of surface shapes and textures.

Fast non-destructive imaging

Contour Elite XA type analyzer is a non-contact system with a large stage that keeps your sample or part intact and undamaged. Our white light interferometry (WLI) technology achieves sub nanometer precision in obtaining height data, independent of amplification. This means that even if more than one million data points - square image areas - are sampled within a millimeter range, users can collect high-resolution height data in seconds.